PCB DESIGN

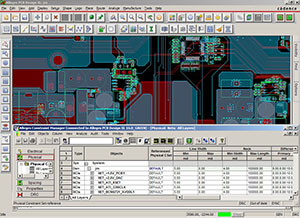

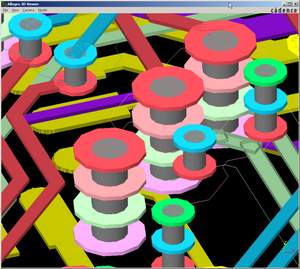

Our Offerings in PCB ServicesGreenmil offer a PCB assembly service that utilizes the latest technology to ensure your PCB assembly is tailored to you and your PCB. Whether your needs are a fast turnaround prototype or a full production PCB assembly we have a carefully selected and monitored partner to suit you. Small and medium businesses typically depend on contract manufacturers to provide the resources, expertise, and labour to launch their products. Our contract manufacturing unit has been successfully operating several years in market. At Greenmil every product is manufactured in compliance to standards. This also ensures that product manufacture is done as per the customer’s, environmental and regulatory requirements. We have thrived in a highly competitive industry primarily due to our unwavering commitment to meet the customer’s specifications, quality and on-time delivery. We offer contract manufacturing from concept to product delivery. From prototype to production, we can fulfil all your manufacturing requirements in the following areas: Selection criteria for prototype PCB assembly includes capabilities for efficiently handling fine pitch BGA and CSP devices, hand loading to avoid programming charges, especially for smaller one to 10 quantities, ability to do consigned versus turnkey PCB assembly, exemplary inventory management control, top-notch test capabilities, component procurement capability for smaller and larger BOMs, as well as the ability to cross reference the parts, which may include hard to find and obsolete items. Flexibility to do machine loading versus hand loading is also important. That’s because the project may deal with small quantities involving moderate technology. Hence, it may be easier and faster to hand load the project. A prototype PCB assembly shop should be flexible enough to do turnkey versus consigned assembly jobs because different projects and different customers have different needs, hence flexibility comes in handy to support them. Component Library ServicesLibrary work is the most critical and time consuming task in the layout chain. We offer a full library creation and maintenance meeting client specific library standards or IPC Standards. Our innovative PCB Footprint review process ensures zero defect footprints. We have experience in executing library services for some of the top EMS companies in the world. We have a dedicated library team to quickly turnaround your new symbol requests on a daily basis also. Libraries are developed in strict adherence to IPC 7351 standards. All the naming conventions, component orientations are as per this standard. Padstack namings are used in combination with the land pattern conventions according to the rules established in the IPC-2220 design standards. Padstack, FHS relative to lead size, antipad sizes, solder mask, assembly and annular requirements adhere to the recommendations made in IPC-2221 and IPC-2222. At greenmil we have a huge collection of centralized library in all the industry leading EDA tools. Also we are offering library creation as per different company standards. Design OutputsDepending on the service you have requested, we will create a complete design output package that will include all or some of the following, as required:

|

|---|